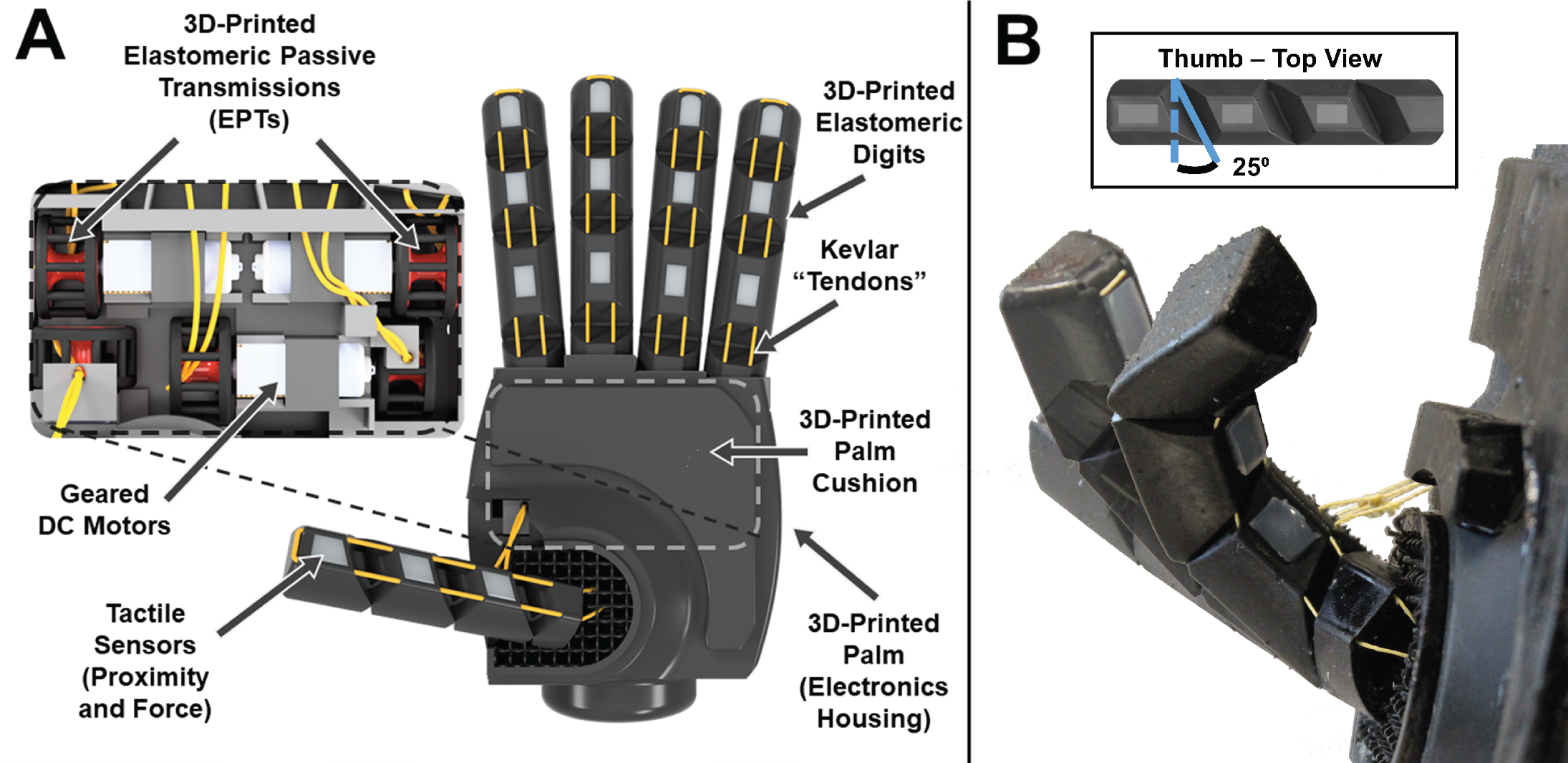

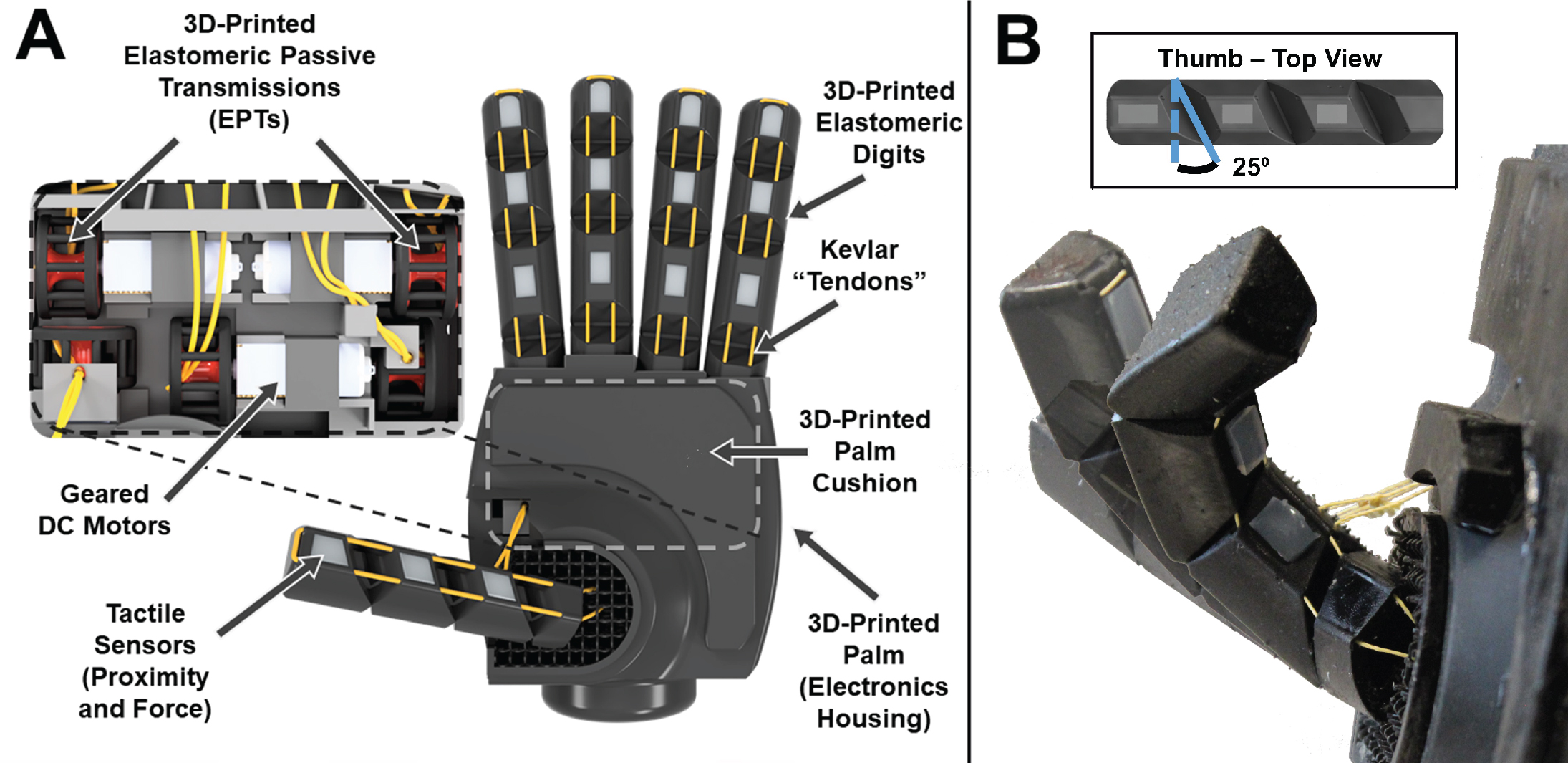

Prosthetic limbs have come a long way from the heavy, solid hands and legs of yesteryear, but it’s still difficult to pack a range of motion into them without complex or bulky machinery. But new research out of Cornell uses a cleverly designed 3D-printed mechanism to achieve speed and strength with simple construction — and it costs a lot less, too.

“Developing prosthetic limbs requires designers to make difficult trade-offs among size, weight, force, speed, and cost of the actuation system,” the researchers say in their paper. For example, they point out, state of the art mechanical prosthetic hands can cost well over ten thousand dollars, with the high-end motors inside alone costing hundreds each. Cheaper hands use cheaper components, of course, which might mean that the hand can grip hard but not quickly, or vice versa.

This is partly because a mechanical hand needs to be able to adjust the force it’s applying very quickly on the fly, and this usually involves some kind of variable transmission or dynamic gear ratio. But Kevin O’Brien and his colleagues developed a new way to have the motor adjust its speed and force without using hundreds of finely-machined components. In fact, it and the …read more

Source:: TechCrunch Gadgets

Previous post

Previous post